The configuration and geometry of chemical reactors determine reliability when assessing the performance of photocatalytic materials. Researchers have developed a novel automated photoreactor for H2 production that substantially improves the accuracy of performance measurements for photocatalytic materials.

Dihydrogen H2 is one of the most attractive fuels due to its high mass-energy content, which is up to three times higher than that of conventional fossil fuels, when used in direct combustion. To date, however, the green production of H2 (using only a photocatalyst in the presence of water and sunlight) has not reached a sufficient technological level, due to a dual challenge: on the one hand, efficient, abundant, recyclable and inexpensive catalysts must bee found. On the other, a photoreactor must be developed that is easy to build and handle for standardized measurements. The rational design of high-performance photocatalytic materials has been the subject of numerous studies over the last decades. However, the lack of precise data concerning mass and energy distributions in operating photoreactors makes it difficult to compare the performance of different experiments, and hinders general progress in the field.

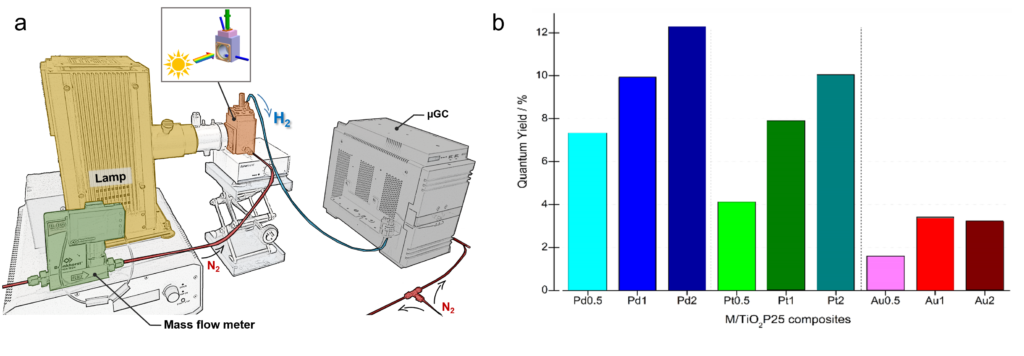

A multidisciplinary team led by researchers from Laboratoire de Physique des Solides, in collaboration with colleagues from the Rutherford Appleton Laboratory and the Universities of Granada, Camerino, Strasbourg and Southampton, has designed a compact automated photoreactor (Figure a) dedicated to H2 photoproduction. TiO2/Schottky junctions, using palladium, platinum or gold nanoparticles, were synthesized and used as reference materials to validate reactor operation during H2 photoproduction. A methodology has been set up to determine local photonic absorption profiles, enabling the local quantum yield for the selected materials to be extracted. This work has been published in Chemical Engineering Journal.

A multi-scale approach was applied to determine the surface and mass properties of each system, and to establish correlations between the observed microstructures and the performance obtained. Interestingly, Schottky junctions (Pd, Pt, Au)/TiO2 show higher H2 production rates and quantum yields (i.e. the ratio of the amount of H2 produced to the number of photons received in the reactor) (figure b), with the exception of Au/TiO2 catalysts. This intriguing result paved the way for an in-depth analysis by electronic energy loss spectroscopy, providing interesting information on the modification of the Au plasmonic mode at the TiO2 interface. Overall, the H2 production capabilities of this work are clearly superior to those of currently established systems, showing that the reactor geometry and configuration could potentially serve as a benchmark in the field and foster new advances in photocatalysis.

Figure. a) Scheme of the experimental setup with the compact photoreactor. b) Evolution of the quantum yield results as a function of the different Schottky junctions and for different noble metal mass ratio.

Reference

A compact photoreactor for automated H2 photoproduction: Revisiting the (Pd, Pt, Au)/TiO2 (P25) Schottky junctions

P. Jimenéz-Calvo, M. Muñoz-Batista, M. Issacs, V. Ramnnarain, M. A. Muñoz-Marquez, X. Li, D. Ihiawakrim, G. Teobaldi, M. Kociak, E. Paineau

Chemical Engineering Journal, 2023, 459, 141594

doi: 10.1016/j.cej.2023.141514

Available on ChemRxiv

CNRS Institut de Physique highlight

Contacts

Pablo Jimenéz-Calvo

Erwan Paineau