Researchers have studied the dynamics of particles contained in a droplet when it evaporates on a fiber. The deposit resulting from the drying on a fiber differs remarkably from the flat surface better known until now, which opens perspectives for industrial issues.

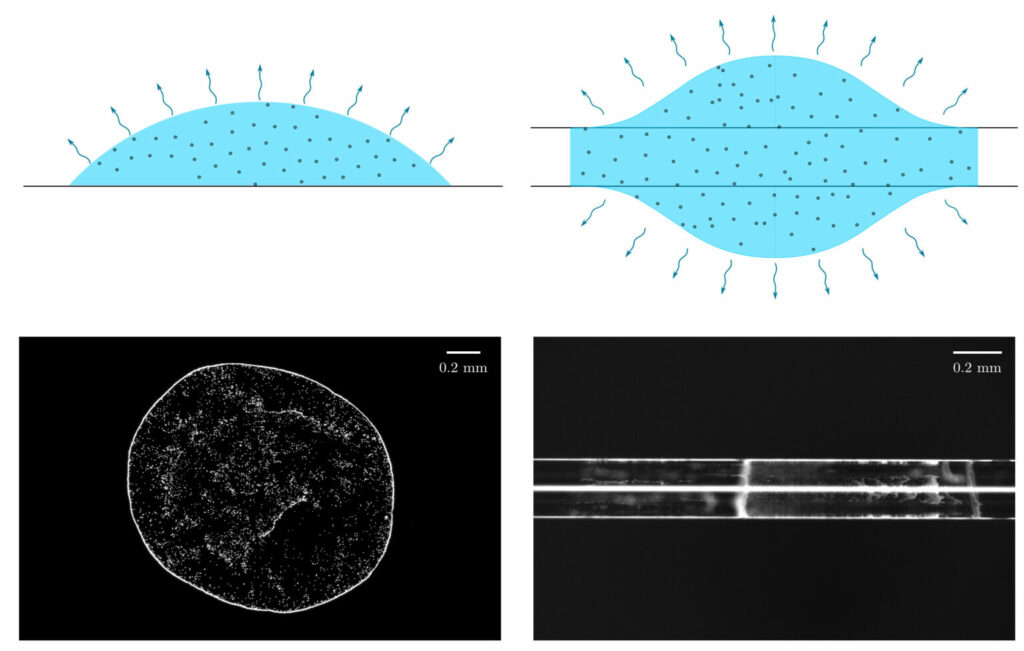

The deposition of particles on a surface by the evaporation of a solvent is a phenomenon that has been the subject of numerous studies since the 2000s. As a perfect illustration of the common coffee stain experiment, the scientific community has been working to understand how the composition of the liquid or the drying conditions could influence this inhomogeneous deposit. Indeed, many applications require controlled deposits such as printing, sample preparation, surface treatment. Among these surfaces, we find planar surfaces, but also curved surfaces such as fibers. It is known that the curvature of the surface can modify the shape of the deposited drop, going from a spherical cap on a plane to a pearl on a fiber (Figure 1).

Figure 1. Comparison of deposits on a flat surface (left) and on a fiber (right). The geometries are schematized at the top and the deposits are photographed by fluorescence microscopy in top view. Note the circular deposition of the drop edge on the flat surface while the deposition on a fiber shows a weak deposit at the initial positions of both drop edges. The particles are one micrometer in diameter.

Researchers from the Laboratoire de Physique des Solides have undertaken to better understand the consequences of the curvature of a fiber on the deposition of particles by drying. To do this, they conducted a theoretical study supported by experimental observations to model the flow in the drop responsible for the transport of particles. A first difference with the flat surface, the drop on a fiber has two disjoint edges, thus independent of each other. Once deposited, the volume of the drop decreases, but the line of the drop edge remains anchored on the surface because of the asperities, which leads to a decrease in height. To ensure the quilibrium of the drop shape, a flow towards the edge is established, bringing particles and reinforcing the pinning of the contact line. On a planar surface, this clinging persists throughout the drying process, resulting in a strongly marked circular deposit. On the fiber, this pinning can only be maintained for a short time, because the drop cannot find a form of equilibrium that would combine the line pinning and the volume decrease. As a result, one of the two lines moves backwards and then stops again for a few moments, and so on, forming deposits that are better distributed over the contact surface of the drop but also more complex and more difficult to reproduce. These results were featured on the cover of the latest issue of Journal of Fluid Mechanics (Figure 2).

Figure 2. These results were published in Journal of Fluid Mechanics. The cover illustration, from this work, is a drop seeded with fluorescent particles on a glass fiber.

Reference

Coffee stain effect on a fibre from axisymmetric droplets

M. Corpart, F. Restagno, F. Boulogne

Journal of Fluid Mechanics, 2023, 957, A24

doi: 10.1017/jfm.2023.59

Contacts

François Boulogne

Frédéric Restagno