Foams are unstable jammed materials whose growth mechanisms remain poorly understood. A recent study has demonstrated a dominant effect of the viscoelasticity of the continuous phase on the cellular structure of the foam.

Foams are dispersions of gas bubbles in a continuous matrix. They are part of a wider family of materials, which includes granular matter, colloidal suspensions, concentrated emulsions etc. who share properties arising from the jamming of the constituents. They are interesting because of their rheological properties, they can be viscoelastic, which is exploited in many industrial products and processes (e.g. food, cosmetics and construction materials).

Foams are also unstable and evolve over timescales comparable to their “time of use”, which makes the study of their destabilisation mechanisms crucial for applications. In practice, many foams are made from complex fluids. This means that that the continuous phase is a viscoelastic fluid, which can increase their stability, as the elastic behaviour can counterbalance gravitational drainage or bubble growth. Bubbles grow because of coarsening, as small bubbles empty into larger ones due to differences in Laplace pressure. This mechanism is difficult to stop or to control, and we still lack understanding of the coarsening mechanism in complex fluid foams.

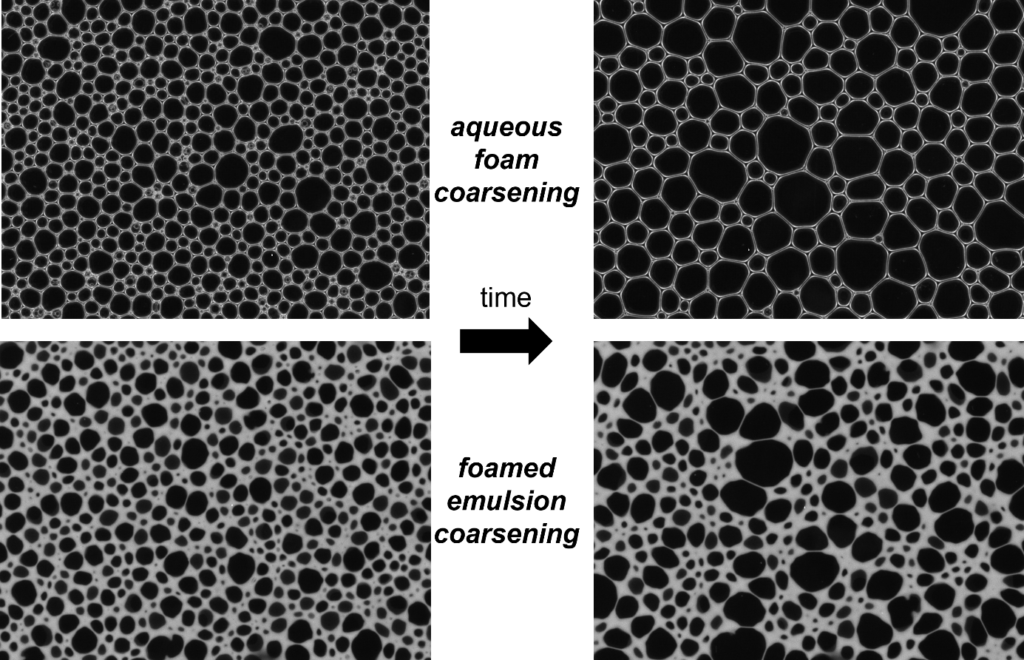

Researchers from Laboratoire de Physique des Solides in collaboration with colleagues from Aalto University in Finland have studied the effect of continuous phase viscoelasticity on foam coarsening with foamed emulsion. The results were published in Nature Communications. They generated a concentrated emulsion (consistency of mayonnaise) and whipped it to incorporate jammed bubbles. A single layer of bubbles (quasi-2D foam) is produced to be able to visualize the complete structure of the foam. The size of the bubbles and their distribution were determined by tracking the evolution of individual bubbles in time. In comparison with foams from aqueous surfactant solutions, they showed that the bubble size evolution is strongly slowed down and foam structure hugely impacted (Figure). This is caused by the interplay between bubble size and emulsion elasticity. This combined with bubble size polydispersity results in highly heterogeneous materials, where separate regions of large and small bubbles can be observed. Stress build up in the unrelaxed structures will be transferred to the foams if dried or solidified resulting in mechanical weakness. The deviation from the traditional cellular foam structure can have other implications on the material properties, so understanding and control of the structural evolution is crucial for the safe design of foamy materials.

Figure. Evolution over time of the structure of foams from an aqueous solution (top) or an emulsion (bottom).

Reference

Viscoelastic coarsening of quasi-2D foam

C. Guidolin, J. Mac Intyre, E. Rio, A. Puisto, A. Salonen

Nature Communications, 2023, 14, 1125

DOI: 10.1038/s41467-023-36763-y

Contacts

Emmanuelle Rio

Anniina Salonen