Is it better to take a smooth or a rough spoon to eat your chocolate mousse? That is the question that a team from the LPS answers by studying the friction of foams on rough surfaces. Their results, published in the journal Physical Review Letters, have shown that the important parameter is not only the size of the air bubbles in the foam, but also the amount of liquid between the bubbles.

Chocolate mousse on a spoon, shaving foam on the skin, sea foam on the beach… There are many situations in which a foam slips or rubs on a rough surface. These are all daily experiences that make you want to understand how a surface interacts with a foam.

In laboratories, when you try to study the mechanical properties of foams, you apply forces to them and deduce how they deform. A classic experiment is to put a foam sample between two flat surfaces and shear it. But if the foam slips when you try to deform it, you can’t measure anything! To prevent the foam from slipping, scientists add bumps larger than the size of the bubbles on the walls of the measuring devices. A question that has remained unresolved until now was to understand what was the minimum roughness size required to prevent a foam from slipping.

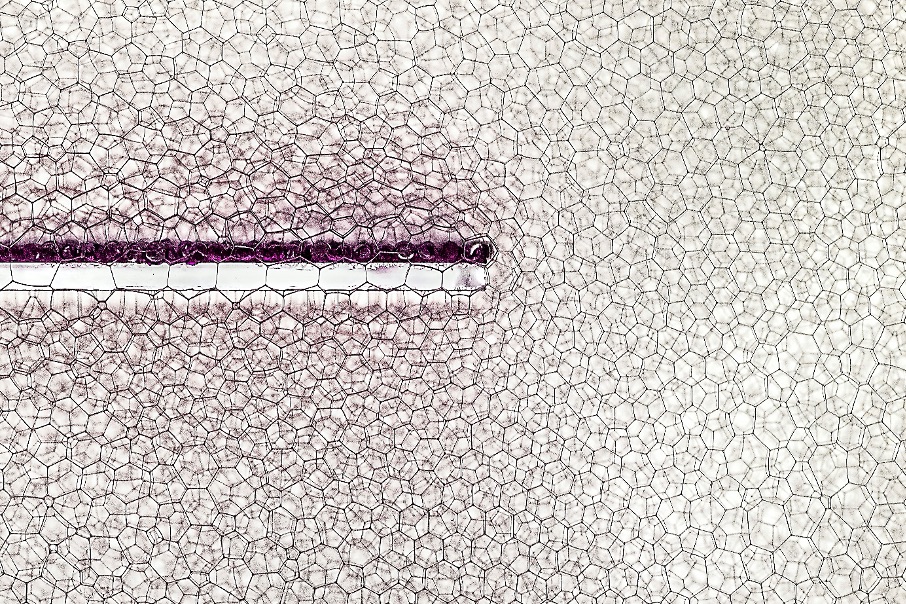

For this reason, a team from the LPS systematically studied the friction of foams on surfaces of various roughness (see figure 1). They made foams made of same-sized bubbles, and precisely controlled the amount of water in the different foams. They measured the force exerted by the foam on glass surfaces for which the roughness had been modified by gluing small glass beads (tens to hundreds of micrometers in diameter). At the same time, they observed the motion of the soap films near the moving rough surfaces. This allowed them to identify what controls the friction of foams.

For sliding surfaces, it is the size of the roughness that counts; for foams, the important length is not really the size of the bubbles but rather the size of the liquid channels between the soap bubbles, called the “radius of curvature of the Plateau borders”. This result was not expected because in other complex fluids, such as granular fluids, it is the grain size that is important.

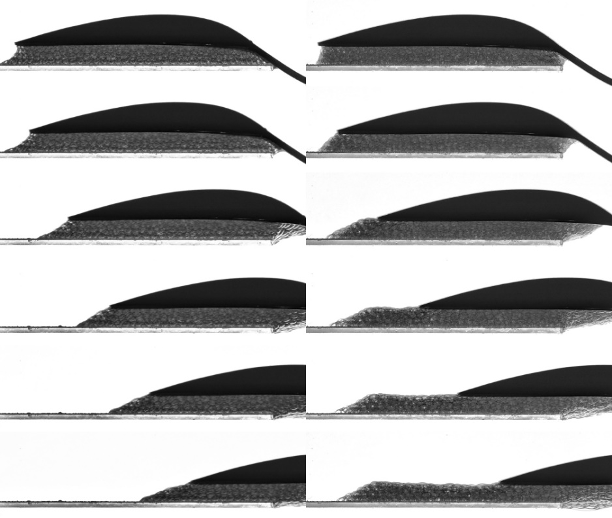

In particular, the research team identified three foam friction regimes. When the asperities are very small compared to the radius of curvature of the Plateau borders, the foam slips. When these two sizes are comparable, the foam slips and then adheres to the surface alternately, creating a stick-slip movement. In these first two regimes, the foam moves on the surface and is not deformed. Finally, when the roughness is much larger than the curvature of the Plateau borders, the soap films of the foam remain anchored on the roughness of the surface. Soap bubbles can no longer slide on the wall, thus they slip between them and the foam is deformed.

One of the novelties of this work comes from the description of the stick-slip friction regime, which is an intermediary between sliding on a smooth surface and anchoring the soap films on a very rough surface. On the other hand, the identification of the three friction regimes makes it possible to predict the size of the asperities to be added to a surface in order to avoid the slipping of the foam. We can therefore know what the minimum roughness of a spoon is in order to properly carry a chocolate mousse!

In the opposite case, where the roughness is fixed, as is the case with the size of the papillae of our tongues, we can now design foams with more or less liquid or with larger or smaller bubbles depending on the texture we wish to obtain for our culinary preparations (see figure 2). Eventually, one could imagine that these studies could be used to adapt the foods provided to patients with swallowing disorders (dysphagia) who are very sensitive to the food texture. Cosmetics could also be adapted to the skin texture of consumers, or the amount of bubbles to be added to concrete could be estimated based on the roughness of the material to which it will be applied.

References

Roughness-Induced Friction on Liquid Foams

Manon Marchand, Frédéric Restagno, Emmanuelle Rio, & François Boulogne

Physical Review Letters 124, 118003 (2020)

doi:10.1103/PhysRevLett.124.118003

Contact

Manon Marchand

François Boulogne

https://www.equipes.lps.u-psud.fr/mmoi/